| News

Release |

@flexo CTP open a new era of photopolymer plate making |

CTF inkjet vs Photo film

A matured new application for film making

(Up to 175 lpi 1% dot reproduction good for color jobs)

Hilson Huang / NozzleBlack CEO

Although CTP (Computer To Plate making) is widely used in offset printing industry for years, but it is not all of the offset printers are using this CTP system. Conventional offset printing machine still needs to make positive film first for PS plate image exposure. How can these conventional offset printers are able to enjoy this new digital inkjet technology for their plate making especially when photo film is facing termination and price of it is getting higher and higher day by day due to fewer and fewer photographic film manufacturer in the market.

By using photo film, the expensive investment of equipment such as image setter, film processor are too huge a sum for them to put in, though second hand CTP machine retired from offset is cheaper but it is facing another problem: termination of production and discontinuing supply of parts ... which means not only no more hardware maintenance but also any after service is available.

This will be a nightmare for all existing photo film users which they have to face in near future before it is too late. Fortunately, due to new technology of inkjet nozzle development with improved RIP software for fine dot reproduction the inkjet film making is ripe and mature for the industry now. Users only have to do more adjustment of their mind that black image is no longer to be made by photographic film any more.

No more developer, no more fixer (no chemicals) with no expensive investments for equipment as well as maintenance and electric power consumption, most important advantage is that due to use of no chemical it is very green and friendly to our environment.

Case 1

There is an offset printing factory YF in Tainan which is in the south part of Taiwan, they relied on outsourcing of film to make PS plate for their Roland 200 / Roland 700 and Komori S40 printing machine. Now they are using NozzleBlack inkjet printer making their own film with NozzleBlack PS-RIP software since beginning of 2014, doing wonderful jobs in big size (and the size is accurate in registration) at very low cost for their routine works, the boss is very happy with this inkjet film making system.

This big size printer operate with NozzleBlack PS-RIP special and fine image forming technology can accept HQ-RIP with 1 bit TIFF signal through ink drop control from Adobe in order to distribute ink accurately on film in accordance with the size directly. The size can be from A4 to 1118mm in width and limitless in length.

Case 2

SH is a plate trade shop in New Taipei city, they have relied on out sourcing of the negative film for a long time so they have paid much more attentions to the inkjet CTF. But the fact they have seen is that when the printer works smoothly, it is good, but once it break down there comes the problem and almost has to stop for a long time. The reason is that most of the system sold in the market:

printer / RIP / ink / film always happen different problem and separately, there seems no one is integrated all together in a package.

Mr. Su, the boss with his wife they want very much to have their own CTF system for film making. Now they are having the concordance from a vender who supply with RIP / Ink / Film which are all certificated by the printer maker,

When Mr. & Mrs. Su are enjoying the quality negative as good as photo film with high opaque black density made by them self, meantime they are also enjoy the wonderful after sales service from the printer dealer for they are using all the materials certificated by the manufacturer. Now they do not have to worry about printer out of order or break down at all.

Case 3

WG co. is a color label printer especially for electronic field which is a most quality demanding printing job of 175 lpi and 1% reproduction in label industry, due to heavy investment of a digital CTP equipment and peripheral machine, they do not want to invest so much.

RIP of NozzleBlack is created by a group of engineers who have at least 20 years of practical experience of color separation and screening who knows what are the difference and important points for an inkjet film user from the beginning when they organize the software in addition to the fine dot reproduction and sharp image. The boss Mr. Tsen is very happy with the results of negative made by inkjet printer now.

@flexo CTP open a new era of photopolymer plate making

Vacuum contact problem with air in between negative film and plate is always a

nightmare for photopolymer plate making over 80% of defected plate which make

image not sharp and clear and become not usable because of this.

CTP inkjet make direct image on plate can solve this problem 100% in addition due to

no more vacuum procedure is required, therefore the procession time can be reduce

over 20 minutes of escaping air and drawing down time.

more...

|

Direct-inkjet technology for flexo plates |

|

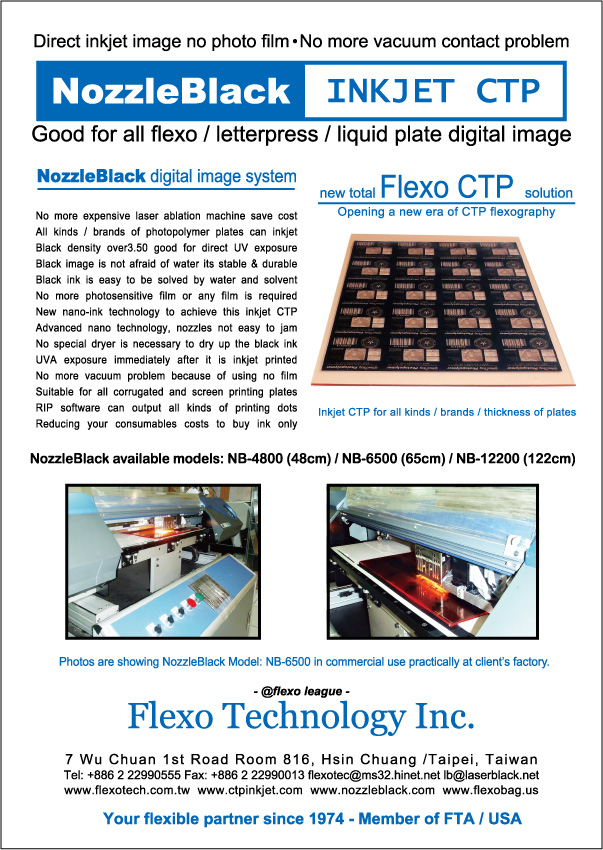

New CTP Inkjet -- NozzleBlack |

|

New CTP Inkjet |

Due to NozzleBlack, its easy to inkjet black image with density

over 3.50 on tracing paper and any non-coated film as a negative

for plate exposure.

RD team of @flexo league has tried to print it on photopolymer

plate directly as CTP plate (Computer To Plate) and find the result

is good and vacuum is not required any more.

In China Print 2013, @flexo is announcing this new total solution of

CTP inkjet system at booth E12-062 welcome your visit. A rival in

the industry gives comment this CTP inkjet may open a new era of

future flexo plate making.

more...

NozzleBlack digital direct inkjet – Flexo CTP

Hilson Huang / CEO - Flexo Technology

In May 2012 during Drupa, a new machine of digital inkjet printing press was shown and have been commended as a great innovation after Mr. Johannes Gutenberg had invented a printing press. As a matter of fact it was derived from electronic image forming technology by liquid electro-ink method in 1993 during IPEX, by using magnetic field reaction to form an image on a roller then transfer to paper or substrate.

After 20 years, direct image to photopolymer plate by inkjet printer – CTP INKJET for photopolymer plate making without using any film is also becoming popular.

Actually, this is an extensive development of CTF (Computer To Film), due to new Nano-ink technology, CTP (Computer To Plate) INKJECT is now practical, ordinary, economic and substantial with more versatility of wider range for substrate selection. NozzleBlack can inkjet black image to any untreated film and uncoated paper as tracing paper which is a cheapest translucent paper material for negative making as a film in stead of photosensitive films. in May 14-17 2013, CTP INKJET for photopolymer plate making was announced in China Print by which a new era of Flexo CTP is opened.

Conventional photographic film manufacturers have announced to terminate their production, this has scared most of the users, film price increase day by day thus has forced consumers to pursue other methods in stead. Due to Nano-ink technology, nowadays to prepare a dye in 20 nano as raw material is no longer difficult, plus additives for the dye, it is easy to have a ink layer by inkjet at 40-50 nano and reaching the same density as offset ink layer which is 400-500 nano, however the consumption of ink is only 10% only, no matter it is an ink layer of color reflection or black opaque to block light transmission when forming the plate image by UV lamps. This is the reason why we can use the ink to spray image directly on the photopolymer plates as a negative film with 0-distance with plate, despite it’s a letterpress plate or flexographic plate in any thickness from any brand. www.ctpinkjet.com

Specialty of nano-ink

Nano-ink can absorb and reflect more light than a regular ink so that reproduction of a dot is showing sharper, slippery, even and more shining in order to reflect more colorful areas of YMCK inks and most important is 15% more color reflection than an offset printing ink layers. This is the specialty of nano-ink which is reducing ink absorbed by the substrate in order for shining up more colorful. Moreover, with thinner layer of nano-ink inkjet printers can spray it at higher speed, no mater it is a treated or untreated surface, film or paper with no coagulation or spreading at all or even on any photopolymer plate material which is available from the market.

CTP Inkjet spray

NozzleBlack CTP inkjet is using a spray head with 2 sets of YMCK each for color printing in total of 8 nozzles. For negative image spray we use only K ink in black color. Depends on the ink density, once the opaque is not good enough then we suggest to use 2 nozzles to spray K ink at a time, thus will assure the black optical density over 3.50 which is excellent enough during plate making in order to block out the UV light and keep image sharp despite of it is a rough image or fine image. Meantime, the other

6 nozzles can be spared for future use.

Advantages of CTP Inkjet

˙Nano-ink

Nano dye with additives can allow ink drying quickly on non-treated substrates, the cost is cheaper than UV based ink and no UV curing device is required so as to purchase a very expensive laser image ablator, which will save you a lot from hardwares.??

˙Ink saving

Comparing with offset printing ink layer the CTP inkjet ink layer is only 10% in thickness which means that ink cost can be reduced a lot not only in consuming quantity but also cost of transportation.

˙Energy saving

No UV curing or extra drying unit is necessary when using nano ink, therefore it is also saving energy, after inkjet only a small bulb on the printer will dry up the ink quickly, this will also reduce problems of nozzle blocking.?

˙Reducing costs

Use no more photographic film so the film cost is reduced. Due to use of nano ink a A2 sized plate will consume only 4 cc of black ink but able to achieve optical density over 3.50. Thus will not have to use Digital plate any more which is about 30- 40% cost up than a conventional photopolymer plate.

˙Any substrates

Wide range of substrates can be used and no special treating or coating is required therefore, can inkjet on any letterpress plate, flexographic plate, water wash flexo plate as well as for liquid photopolymer plate making. RD team finds that direct image on film for liquid resin spreading can be also sprayed in order for resin contact directly to the image with 0-distance. This has solved no-sharp-reproduction bad impression from the beginning when liquid photopolymer plate making technical had been invented.

Conclusion

NozzleBlack CTP inkjet for flexo no film plate making is not using a special printer but a regular printer which you can get from the market only we have paid more attention to the portions of: fine reproduction, easy access, less breakdown as well as reasonable hardware cost so that it can be accepted by the industry easily no mater how big size is required. This is quite different from a kind of small size A2 machine available in the market but only good for thickness less than 2.30mm from which the market is divided.

In summarizing, a new era of CTP inkjet for photopolymer plate making is opened right after the China Print show in 2013, as Jessica Harkins reported on the Flexo magazine there is a wide array of people will make up the flexographic industry, business owners, design partners, creative brains, old-school fundamentalists, young techs and everyone in between will work together to make flexo industry stronger. NozzleBlack is expecting here the flower blossom. www.nozzleblack.com

@flexo CTF / CTP PRINTER SPECIFICATIONS

NozzleBlack Models |

NB-1080 |

NB-0610 |

Printer Technology |

Drop-on-demand Micro Piezo Inkjet Technology |

Print Head Nozzle Configuration |

180 nozzles x 8 lines |

Print Height Adjustment |

1.20mm-2.00mm |

Ink cartridge |

Ink Types |

NozzleBlack Nano Black Ink (k) |

Capacity |

220 ml Cartridge (+-5%) |

Maximum Media Width |

1.080 mm |

610 mm |

Minimum Media Width |

150 mm |

Media Thickness |

0.30mm ~ 1.30 mm (CTF) 0.50mm-7.00mm (CTP) |

Maximum Roll Media Weight & Media Core Diameter |

19 kg / Φ 150 mm

(3 inch core / 2 inch core) |

5 kg /Φ 100 mm

(3 inch core / 2 inch core) |

Maximum Print Width |

1.074 mm |

604 mm |

Print Margin |

3 mm (front) / 3 mm (Back) / 3 mm(Left / Right) |

Print Resolutions |

1440 dpi / 720 dpi / 360 dpi |

Maximum Production Speed (※1) |

A1 size Printing : 33 seconds |

Interface |

Ethernet 100BASE-TX/10BASE-T |

Printer Language |

MH-GL,MH-GL2.MH-RTL +ALL GRAPHIC SOFTWARE |

Memory |

256 MB |

Drying Heater |

Adjustable up to 40 degree C |

Power supply |

AC100-240 +-10% (50 / 60 Hz) |

Power Consumption |

Power OFF |

1 W |

Operation |

100 W |

Noise Level |

67.7 Db |

Operating Environment |

Temperature 10~350c / Humidity 40~60% |

Certifications |

MET(USA), CE(EU), FCC(USD), VCCI(JAPAN), RoHS(EU), CB REPORT |

Dimensions (W x D x H) |

(W) 1.772 mm x (D)504 mm x (H) 983 mm |

(W) 1.192 mm x (D)504 mm x (H) 357 mm |

Printer Weight |

Body |

45.0 kg |

30.5 kg |

Stand |

16.5 kg |

12.5 kg |

Packing Dimension |

Body |

(W) 1.905 mm x (D)630 mm x (H) 581 mm |

(W) 1.343 mm x (D)652 mm x (H) 510 mm |

Stand |

(W) 1.510 mm x (D)435 mm x (H)260 mm |

|

G/W |

90 kg |

70kg |

|

Big brother of LaserBlack - NozzleBlack |

An inkjet black enhancing system “NozzleBlack” has been created for big format negative making.

The black density can reach 3.50 and quality is as well as LaserBlack which is good for photopolymer

plate making of long time exposure. The width is from 48 / 65 / 122 cm x limitless in length.

By using contemporary technology of nano-ink, “NozzleBlack” is now available in

high black density and can be printed on any untreated film or tracing paper (vellum) as you like in

order to save your film cost, no special media or special coating film is necessary any more.

Now with this new “NozzleBlack” system, you can have your negative as big as you like and the

cost is only 25% to 30% of the photographic film (image setter film). Now you can really say

good bye to photo film. more...

|

Young brother of LaserBlack Enhancer |

LaserBlack LB – Spray – Kit

In order to have enhanced service to small negative film required card, tag, label and stamp makers, LaserBlack has newly introduced its younger brother LB–Spray-kit and put it into on-line-shop. The LB–Spray-Kit is including 500 cc of LaserBlack Solution with a micro spray bottle to fill, a quick black gun to dry and tracing paper in order for buyers to start making negative at opaque density dark enough right the way after receiving the kit.

The result from this spray is as good as from a LaserBlack Enhancer no matter it is a printon tracing paper or transparent film. No use of aerosol gas therefore it will not 80% go to air and only 20% in use any more. This is a cheapest way of negative film making method for the printing industry.

LaserBlack Solution is water base, please use tap water to wash off your hand after the process. Low evaporation, non toxic, not harmful to your health. Do not use high pressure gas, non explosive and solving problem of high cost of transportation.

Welcome to upgrade to use LaserBlack Enhancer in order for making negative film more cheap, more quick, more smooth, efficiently and perfectly during this period of time lacking of photographic film.

www.laserblack.net • lb@laserblack.net

|

Paper World 2012 / Shanghai China |

Paper World 2012 / Shanghai China

On September 19-21 @stampBag and LaserBlack have shown

successfully in Shanghai at Taiwan Pavilion.

During the exhibition we have first announced our @stampBag A7 kit which is an economic package for stamp making with machine and materials good for 200 pieces of 8 x 10 cm stamps and exposure machine can be reuse for long.

@StampBag is an innovative way which is economic and convenient

method to make stamp by photopolymer resin-in-bag after exposure just washout by water. A stamp with any design can be made within 15 minutes while your client is waiting.

LaserBlack is a quick way to make a negative film just from your HP laser printer then go through this enhancer in 3 minutes you can have your negative film ready for exposing. Combination of @stampBag and LaserBlack is also good for DIY and educational purpose. For more details please visit www.stampbag.net .

|

Feedback from customer in South America |

Feedback from customer

in South America

Good day! I want to comment to you that we have been working very well all the time with flexo making plate you sold us since 2010 and also plates have a good quality and they are more flexible than former plates we had before.

The HP 5200 A 3 printer which we have bought from you is working very well with your LaserBlack Enhancer which enable us to make our own negative film any time in our factory at very low cost and it is very convenient.

As to the Model @A2SSF flexo plate making machine, which is also performs very nicely of all the functions : Exposure + Washout+ Drying + Anti-tack treatment 4 in 1. Due to all stainless steel made, it looks as new as the time we have bought it two years ago.

This time I want ask you quote us sheet @flexo plates like last time. Please quote all goods price under C&F Arica, Chile in American dollars, we will take insurance from Taiwan to Bolivia, please do not don't worry about it although we know the freight maybe expensive, but we still like to buy from you.

We appreciate very much that only you can provide the

total flexo plate making solution for our one-stop shopping

requirement including: prepress + materials + plate + equipment in once and one shipment.

Thank you once again and have a nice day.

Best regards,

Marcelo Lizarazu Orellana

FIMAR LTDA.

Tel: 591-2-5249985/5242613

Oruro , Bolivia . (110831)

|

Celebration of 10000 units – extra gift sale |

Celebration of 10000 units – extra gift sale

ON-LINE-SHOP SPECIAL

LaserBlack International is celebrating 10000-units sell of their LaserBlack enhancer since first announcement at 2002 SGIA Show in Mississippi St. Louis USA .

The black density enhancer is a simple idea to coat a solution all over a toner printed page which is printed on a tracing paper (vellum) or film by a laser printer.

After drying the coated solution is melting the toner and become a black layer upon the image area without any diffusion so that opaque density is enhanced 300-400% which is good enough for any kinds of plate making and its as good as a photographic film or a film outputted from an image setter.

This unique enhancer has been granted inventions / patents in 35 countries and has been exported to 65 countries including developed countries, developing countries and under developed countries.

All the users are happy to have this simple and easy unit as their personal image setter, especially when it is very convenient and economic to make negative / positive film for label / news paper / screen / bag / corrugated board printing and stamp making.

Now they are running a campaign of “ 10000-units celebration special” with extra gift

for on-line shopping. All kits are including the enhancer A4 / A3, a Quick-Black dryer and 500CC of LaserBlack-Solution which can process 1000 sheets of A4 or 500 sheets of A3. Plus extra gift of 500CC to make it 1 liter now.

www.laserblack.net lb@laserblack.net

|

Laser Black used for Corrugated plate making |

How is Laser Black Enhancer used as negative for @flexoBag System plate making.

(Seminar of @flexoBag System was held during Tigax exhibition period in October 2010.)

Laser Black Enhancer is providing low cost negative film for @flexoBag plate making.

(Hilson Huang, CEO of FTI is delivering a speech of @flexoBag system by presenting a DVD.)

|

New EZ series A4 plate maker On Line Shop special ! |

Combinating with Laser Black, now @flexo plate maker Model EZ A4 is available

On Line for making Letterpress,flexo and liquid photopolymer plates for label,

form, card,tag, PAD printing and stamp making.Now you can make your own negative

film and plates by yourself at very economic investment at high productivity,

to save time, labor and money. Click to get Shop Special from here.

|

The 5000th Unit Laser Balck Enhancer Special Campaign ! |

Innovative negative making machine for all kind of plate making,

Laser Black Enhancer is conducting its 5000 units sale campaign.

Welcome to our exhibitions of Sino Corrugated 2009 Shanghai

and China Print Beijing to be our 5000th user with special offer.

|

|

Exhibition event for 2009 : SINO CORRUGATED / CHINA PRINT:

|

Sino Corrugated : April 7 -10, Hall E5-Y160 Shanghai International Exhibition Center

China Print : May 12 -16, Hall W3-073 Beijing New International Exhibition Center

Topics: Newly developed and patented FlexoBag plate making system by Liquid photopolymer.

Live demonstration water-base plate making to reduce 50% of cost and protect your life.

|

|

MY IMAGESETTER |

MY IMAGESETTER --- Recently imagesetter film price is going up and up no matter it is the made by your own or relied on film outputting service cost, therfore we have found the demand of our Laser Black Enhancer has appreared increasing and increasing.

We heard from many film manufacturers that due to material price increased continuously, they are quiting the production of photographic film for negative / positive making and the cost of this film will be going higher and higher in the future.

LB-Enhances are very acceptable by the screen printers for this is the most economic and quick way of geting a film for plate making from your own laser printer ---- AS YOUR OWN IMAGESETTER.

Many conventional gravure cylinders and plate makers told us that it is very convenient for them to prepare the film for their plate making from Laser Black Enhancer due to price up of the film and film outputting services. Their jobs are from pad printing plates to film package printing cylinders.

Corrugated board printing plate makers love Laser Black Enhancer in A3 size very much due to convenience of their negative making and use no camera any more, therefore in many areas like in Taiwan and China almost every corrugated plate maker have one unit of LB-Enhancer with them, time and money saving are the reasons why they like Laser Black System so much.

Label printers like to have Laser Black Enhancer in A4 size for they can use either tracing paper or vellum or transparent film to make negative printed from a laser printer then enhanced by Laser Black to have teir own film to make plate quickly. For color separantion jobs, they may rely on imagesetter service to do it for them because it is too expensive.

For small label printers this is a good way to save time and money in order for plate ready to print, to have a small unit of plate making machine making their own plate for letterpress or flexographic printing is a must for them to reduce their time and cost is becoming a trend in the world.

From all these points of view, it is not the question of Laser Black System can be used by you or not, it is depends on you to use it immediately to save time and money, the quicker you decide it will save you much more. Again for the critical jobs, you may rely on out sourcing.

|

|

Applauses from Laser Black users |

|

|

COMPANY |

COUNTRY

|

|

COMPANY |

COUNTRY

|

1 |

Polymung Bag Manufacturing |

South Afica |

|

BELARUS |

RUSSIA |

2 |

S.C. Auradan |

Romania |

94 |

UNITED |

Bahrain |

3 |

GJS Machinery |

Australia |

95 |

SAKARYA |

TURKIYE |

4 |

ADANCE |

USA |

96 |

Union Inks |

Philippines |

5 |

A.P. Zeefdruktech |

The Netherlands |

97 |

Aslanidis |

GREECE |

6 |

ADANCE |

USA |

98 |

ELFAYROOZ |

EGYPY |

7 |

CF CARD |

Malaysia |

99 |

Colour |

Australia |

8 |

Caesar Pac |

Kuwait ` |

100 |

Kyriakos |

GREECE |

9 |

USAHA SHANLAI |

Indonesia |

101 |

VASCO |

HUNGARY |

10 |

HANKOOK |

Korea |

102 |

GREEN |

IRAN |

11 |

P.T. BALI MAS |

Indonesia |

103 |

PARSIAN |

IRAN |

12 |

UTOMO |

Indonesia |

104 |

FLEXOGRAFF |

BRAZIL |

13 |

CF CARD |

Malaysia |

105 |

ADNACE |

USA |

14 |

WIHANI GROUP |

Indonesia |

106 |

COLOUR |

Australia |

15 |

CF CARD |

Malaysia |

107 |

IF |

India |

16 |

PT.BINTANG |

Indonesia |

108 |

GREENPNS |

Korea |

17 |

NUMRUNG |

Thailand |

109 |

MATHIAS |

Bahrain |

18 |

REPRO VISTA |

Indonesia |

110 |

JENTAT |

Malaysia |

19 |

PT. MASTER |

Indonesia |

111 |

CPH |

Switzerland |

20 |

PT. Nusantara |

Indonesia |

112 |

GREENPNS |

Korea |

21 |

CMT |

Mauritius |

113 |

IF |

India |

22 |

PT. BINTANG |

Indonesia |

114 |

Flexo Printing |

South Africa |

23 |

ADANCE |

USA |

115 |

VASCO |

HUNGARY |

24 |

VASHNAVI |

INDIA |

116 |

ADNACE |

USA |

25 |

SHRESTHA |

NEPAL |

117 |

ALTER |

ARGENTINA |

26 |

Zion of Printing |

Korea |

118 |

ABS |

Malaysia |

27 |

Grapack Asia Inc |

Philippines |

119 |

CF CARD |

Malaysia |

28 |

MEGA |

Malaysia |

120 |

GALAXY |

Cyprus |

29 |

HANI FLEXOGR |

Korea |

121 |

ADNACE |

USA |

30 |

Graptec |

Singapore |

122 |

IF |

India |

31 |

AL RIZQ |

U.A.E. |

123 |

HNB |

Korea |

32 |

ADANCE |

USA |

124 |

KEBEDE |

Ethiopia |

33 |

Mili Plastic |

Malaysia |

125 |

DKSH |

Indonesia |

34 |

Grapack Asia |

Philippnes |

126 |

TIME |

Thailand |

35 |

CF CARD |

Malaysia |

127 |

ADNACE |

USA |

36 |

ADANCE |

USA |

128 |

COLORPAK |

Papua New |

37 |

LEADMAN |

Singapore |

129 |

ARAPOUSH |

IRAN |

38 |

Graphic Systems |

Bangladesh |

130 |

George |

U.A.E |

39 |

ADANCE |

USA |

131 |

HAND |

Austria |

40 |

CF CARD |

Malaysia |

132 |

Trinity |

H.K. |

41 |

CENTRAL |

Jordan |

133 |

Graphic |

Bangladesh |

42 |

MEGA |

Malaysia |

134 |

OTO |

Simonova |

43 |

TechNova |

India |

135 |

COPYWARRIOR |

GERMANY |

44 |

PAD |

ESPANA |

136 |

PUPPERT |

GEMRAMY |

45 |

TRIANGULAR |

Saudi Arabia |

137 |

CAMSTAT |

Canada |

46 |

R N VASWANI |

India |

138 |

GEORGE |

U.A.E. |

47 |

Zion |

Korea |

139 |

KDS |

Poland |

48 |

GMS |

Australia |

140 |

CV |

Indonesia |

49 |

Egmont |

India |

141 |

CHRISTER |

SWEDEN |

50 |

ADANCE |

USA |

142 |

ID |

Belgium |

51 |

Benny |

ISRAEL |

143 |

NOBEL |

Malaysia |

52 |

Zion |

Korea |

144 |

ROYAL |

Philippines |

53 |

CPB |

Germany |

145 |

UGYV-SZERV |

HUNGARY |

54 |

ADANCE |

USA |

146 |

PRINTY |

Poland |

55 |

Mapal |

Israel |

147 |

CODPRESS |

Mongolia |

56 |

Graphic Systems |

Bangladesh |

148 |

FUM |

Philippines |

57 |

Lithomecanmica |

GREECE |

149 |

Lisner |

Israel |

58 |

Zimco |

Lebanon |

150 |

PRINTY |

Poland |

59 |

WDH TUNG |

HongKong |

151 |

TAISAL |

Vietnam |

60 |

POLYDLAM |

England |

152 |

ABS |

Philipines |

61 |

CPB |

Germany |

153 |

DPJ |

Sri Lanka |

62 |

CPB |

Germany |

154 |

PT. TOSI |

Indonesia |

63 |

CHOKE |

Thailand |

155 |

Printrans |

Malaysia |

64 |

ADNACE |

USA |

156 |

HWD |

Germany |

65 |

MOHAN |

India |

157 |

GEORGE |

U.A.E. |

66 |

CHOKE |

THAILAND |

158 |

SUPERIOR |

Macedonia |

67 |

Y.POLAD |

ISRAEL |

159 |

BELL |

Israel |

68 |

PERAL |

EGYPT |

160 |

|

Germany |

69 |

FG |

CROATIA |

161 |

Gravure |

THAILAND |

70 |

UNITED |

Bahrain |

162 |

Scott |

USA |

71 |

PONGER |

ISRAEL |

163 |

Voraustechnik |

MALAYSIA |

72 |

NETA |

ISRAEL |

164 |

ADNACE |

USA |

73 |

BEN |

Austraila |

165 |

Walcar |

Australia |

74 |

RIMO |

Switzerland |

166 |

Nesta |

CROATIA |

75 |

ADNACE |

USA |

167 |

IP IGNATOV |

RUSSIA |

76 |

Prelude |

ISRAEL |

168 |

NORWAY |

NORWAY |

77 |

Ballon |

Switzerland |

169 |

COLOTH |

Greece |

78 |

Embassy |

Isreal |

170 |

ZENITH |

INDIA |

79 |

NNP |

Thailand |

171 |

COLOP |

Austria |

80 |

Dragon |

Mauritius |

172 |

ALEX |

Kazakhstan |

81 |

PRINTY |

Poland |

173 |

MICHELE |

ITALY |

82 |

PIONEER |

U.A.E. |

174 |

COLOP |

Austria |

83 |

Apparel |

Canada |

175 |

JIRIANI |

PANAMA |

84 |

Fuxin |

Thailand |

176 |

DICKSON |

Australia |

85 |

Fuxin |

Thailand |

177 |

Rohit |

U.S.A. |

86 |

Martin |

Germany |

178 |

MaryAnne |

U.S.A. |

87 |

Labelqwik |

South Africa |

179 |

COLOP |

Austria |

88 |

COLOUR |

Australia |

180 |

Hodod |

Saudi Arabia |

89 |

COLOP |

Austria |

181 |

Darbest |

Morocco |

90 |

CHRISS |

Australia |

182 |

FIMAR |

Bolivia |

91 |

COLORPARK |

New Guinea |

183 |

MARK |

U.S.A. |

92 |

FUXIN |

Thailand |

184 |

COLOP |

Austria |

93 |

MATIC |

Jordan |

185 |

Marcos |

U.S.A |

186 |

Jipushen |

S H |

|

|

|

187 |

HNOS |

SPAIN |

|

|

|

188 |

Zerba |

Slovenia |

|

|

|

189 |

TORPEDO |

FRANCE |

|

|

|

190 |

MaryAnne |

U.S.A. |

|

|

|

191 |

Glowboy |

Australia |

|

|

|

192 |

Graphic |

Bangladesh |

|

|

|

193 |

The printed |

Canada |

|

|

|

194 |

FORPEDO |

FRANCE |

|

|

|

195 |

Work |

ITALY |

|

|

|

196 |

Toyoda Stamp |

Japan |

|

|

|

197 |

GHASSAN |

Lebanon |

|

|

|

198 |

Phose |

Korea |

|

|

|

199 |

KLASS |

Russia |

|

|

|

200 |

KESTON |

Philippines |

|

|

|

201 |

SITOM |

Slovenija |

|

|

|

202 |

FADI |

Lebanon |

|

|

|

203 |

WOONG |

Guatemala |

|

|

|

204 |

ABDUL |

UAE |

|

|

|

205 |

COLOUR |

Australia |

|

|

|

206 |

I.L. |

Israel |

|

|

|

207 |

RORP |

France |

|

|

|

208 |

VOJKAN |

Serbia |

|

|

|

209 |

AI |

UAE |

|

|

|

210 |

MP |

Singapore |

|

|

|

211 |

AMS |

Germany |

|

|

|

212 |

ACME |

Australia |

|

|

|

213 |

PATRICIA |

U.K. |

|

|

|

214 |

LA |

Bolivia |

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

|

|

Thanks your visit during Drupa 2008 !

|

We just have a tremendous exhibition in Drupa 2008, for our Laser Black Enhancer / @flexoBag / @flexo plate makers.Its becoming very hot and busy to us. For more details of our products please visit our website individually.For people who visited our booth in Drupa, we will reply to them one by one according to their requirements, we thank you first for your visit and hope to have oppotunity to serve you soon.Meantime, Drupa special on - line - shopping for the Laser Black Enhacer is over, we will carry on collecting the orders by the end of June 2008, you may expect for another special offer until next Drupa on 2012.

|

|

C E |

| CE

Certificate & Declaration of Laser Black

We are very proud to announce that we have

been approved & granted Certificate of Test No. R08022201E,

Meantime CE Declaration of Conformity is also available

for all the EU dealers

and clients from us under your request.

+zoom

|

|

Comparison of Laser Black

Enhancing result |

more...

|

|

SPECAIL OFFER ON LINE SHOPPING |

|

We have created a

new area for ON LINE SHOPPING of Laser Black Enhancer with

a special kit and we will pay the air freoght for you

no matter where are you, please click to email us for

quick access, we will send you a Proforma Invoice with

our bank details for your remittance. Click here for more

details.

|

|

Technical

News report from L&L magazine |

Laser Black using for Label printing………

A report from "Label and Labeling" magazine.

+zoom

+zoom

|

|

Super

Black Toner Cartridge / total solution for your questions |

Super Black Toner Cartridge

/ total solution for your questions

In the case of no more method to improve the darkness

from your printer any more,you are very fortunate to

have our Super Black Toner Cartridge to help you and

slove all your problem.

Not only your can get a darkness result of 20-30 %

higher density from your printer but also very even

and smooth solid to fill all the gaps between the toner

particles, no matter how old is your HP printer. Furthermore

the price is cheaper than an oringinal toner cartridge.

Then go through Laser Black Enhancer, the density go

up to 3.0 - 3.5 which is good enough to expose the longest

exposure time needed 7.00mm photopolymer plate directly.

Thus save money, time and labor, you have to start

with it right the way to earn more for yourself.

|

Premium

offer for World

wide distributors |

Premium offer for

World wide distributors

Laser Black Enhancer is a brand new innovative invention,

now have been granted Invention Certificate in USA,

China, UK and Canada as well as Patents granted by Germany,

Japan, France, Korea, Vietnam Australia, , Hong Kong

and Taiwan. Patents in other countries are pending and

will be granted soon.

This product is now growing to be a new

trend as making positive and negative films for plate

making

in addition to an image setter. Premium

policy for distributors / agents is now open for worldwide

distributors. Welcome to the Laser Black International

family.

|

Feedback

from a Laser Black Enhancer user |

|

Feedback from a Laser Black

Enhancer user

Convenient, quick, easy access and save money.

Do you want to try now? Make up your mind ASAP.

Our company has over 20 year experience in plate making

and printing, to make film for exposing plate, we had

done it by the traditional way of a process camera and

developing by hand in the dark room.

At that time, we have at least 4 persons as a group of

making film, one for art work,

one for typing, one for composition and one for camera.

When it was busy, we have to do it overtime until late

night even sometimes we have one more group people to

make film at night shift

About 5 years ago, we rely on image setter service to

make the film for us in order for us to make plate in

plant. Convenience is that we do not have to touch film

making any more however when sometime it is an emergency

or some problem occurred during printing, we can not wait

and get in time from the service to deliver the film urgently

for our immediate use.

Until recently, Laser Black people introduce and suggest

to use Enhancer directly from a laser printer, then go

through the Enhancer to increase 300% black density with

100% success it is good and quick enough for our job and

production, therefore we decided to tear down our darkroom

as well as move out all the equipments as camera and unnecessary

devices, no need to have an experienced person for camera

and every body can make film simple and easy now.

The image on the monitor can be laser printed on a tracing

paper or film and then enhanced to become a film is incredible

and convenient so that whole process can be done by the

internal network for every body in the factory are all

using computer access now a days.

Under this circumstances, the making of film is getting

more and more which means the jobs rely on image setter

service is also less and less. So that the ratio of printing

and enhancing to make film in our own plant is now up

to 60-70% again. Not only our

boss is happy but also all of us are happy now because

of its convenience and easy access --- We all love Laser Black

Enhancer very much !

At the beginning, we did not count on the enhancer so

much, but gradually, we find

that we save lots of our time, labor and most important

is the cost is very low which means that we get much more

profit from this smart idea and small machine.

Eventually, all of us realized that it is nothing to do

with Laser Black Enhancer can do this or can not do that,

it is only really depends on you to decide to

use it or not in order to save your time, labor and money

immediately which will also give you more advantage and

profit.

Ms Fukami / Gio Lung Graphic

Arts Co. / Linkou - Taipei |

International

Patents |

|

Laser Black

ENHANCER

—INTERNATIONAL

PATENTS—

( PATENT PENDING IN MANY OTHER

COUNTRIES )

|

KODAK

COOPERATION |

|

Kodak Polychrome Graphics (KPG)

has appointed Laser Black International Corp/Flexo

Technology Inc. (FTI) as their distributor of

Flexcel photopolymer plates in Taiwan recently.

Flexcel plates are the latest designed flexo plates in

the world with a new recipe for package printing in three

series of plate: SRH / SRM and SRC for Hard, Midium durometer

as well as C for corrugated board printing.

Flexo Technology Inc. has been in the flexo field for

30 years, not only a distributor of photopolymer plates

but also has their own brand plate making machine and

prepress system for making negative.

After servicing Taiwaness Flexo Market,

KPG will also cooperate with FTI for the China market

which is a tremedous demand for flexo package printing.

Photo shows Mr. Steve Venn / Reginal Manager of KPG (right)

shaked hands with

Mr. Hilson Huang / Managing Director of FTI (left) after

signing the agreement.

|

| @Flexo

Group is particitating the following Exhibitions to show

new developed products and solutions: |

| FESPA 2005 |

MAY31 JUNE 4 |

|

| |

MESSE MUNCHEN |

|

| |

HALLE B1-543 |

|

|

Event |

| March

30 – 2 PRINT South China / Guanzhou

April 5 – 9 PACK Ukraine / Kiev

May 6 – 19 DRUPA Duseeldorf / Germany Hall 8 /

2D48

|

| Exhibitions

will take part in: |

|

April.24 - 27 Indomaf / Print Jakarta /

Indonesia

May 13 - 26 All Print Shanghai / China

May 20 - 23 EmbaxPrint Brno / Czech

June 06 - 09 Thai Print Bankok / Thailand

June 18 - 21 Taipei Pak Taipei / Taiwan

July 03 - 06 Print / Label Kuala Lumpur / Malaysia

July 17 - 20 Printpak Shanghai / China

Sept. 22 - 30 IGAS 2003 Tokyo / Japan

Oct 01 - 04 Philippine Print & Pack / Manila

Nov. 14 – 17 Vietnam Plastic, Pack & Print / Ho

Chi Minh City

Dec. 04 – 07 Andina – Pack, Bogota / Colombia

Dec. 09 – 11 LabelExpo China / Shanghai

|

|

USER'S FEEDBACK |

|

Laser Black - Introduced at the 2002 SGIA show. We

have no experience

with this product, however it appears to make the images

on both our

Translucency and LaserFilm the most opaque we have ever

observed.

We are very anxious to receive customer reports on this

product.

Mike - I followed your link to the Laser Black

site and got in touch with Tony Chu their rep in Los

Angeles. He came down to San Diego to show me the

system and I bought one. Really something else! I

make positives for sikscreening and used to use Laser

Buddy but the laser Black system puts that to shame.

Not only does it make the image twice as dense but

it also fills gaps in the toner. It is a bit more

work but in the long run well worth it for a real

quality positive. I sell a lot of film to printers

in the area and they're all really stoked with the

results as well. If not for your link I'd have never

known about this. Thanks and Good Luck. - JM

James M. Madden

7431 Cuvier Street

La Jolla, CA 92036-5005

I have been using Tony Chu's excelent Photopolymer

wash solution when he introduced the Laser Black for

making our negatives in house,I must say that not

only it worked well, it reduced our cost of negs drastically

and gave us much more flexibility in serving our customers.

I highly recommand it.

Kazem Rezvani

V.P.Operation

Pacific Western Sales

Ever Great Screen Process

Films needed for screen printing supposed to be not

necessary in a high end quality, however, reproduction

by camera and developing in the dark room to make

film for plate making is not a good way for our mass

production jobs as well as too much time consuming.

And most of all we can not afford the high cost to

have film made by an image setter.

For these reasons, we have tried very hard to find

a way to get the image from our monitor to have a

final solution of getting a film for our plate making

just from a printer, so we have tried all laser and

inkjet printers, unfortunately the black opaque is

not enough at all. We also tried to get a black print

from color laser printer (which cost us lot of money)

in order to get more density but still failed.

Until we find and use the Laser Black Enhancer, now

we only use our HP Laserjet printer to print on tracing

paper / film then go through the Enhancer the density

go up 300% immediately after drying. For the fine

image and small dot the reproduction is as good as

it is made by a camera or a setter. In the high peak

season, we can make 1000 sheets A3 size enhancement

in a working day. Laser Black Enhancer is a important

economic high efficient tool for us now.

You may not know that this is also a secret where

our profit comes from!

Taipei / TuChen / Chen Min-Yo

EnChee Label printing

Our company is a label stick printer located far

away from center of city, when salesmen received orders,

they deliver the original to the image setter service

center then bring the film back for plate making the

next day, it is very inconvenient to wait for a long

time and need a courier to get the film back. In case

of any mistake or problem then we have to wait for

another day.

Since we have installed the Laser Black Enhancer,

we can have a negative film right from image on our

monitor in few minutes and ready to make a photopolymer

plate for printing within an hour. We don’t have to

wait so long as in the past any longer and we have

increased lot of our productivity due to the efficiency.

At the beginning, we doubted with the opaque density

from the enhanced quality is really good enough as

a negative film to expose photopolymer plate. Until

we find that the system not only melt the toners in

a very even layer as a coating on the paper / film,

but also we find that gaps between toners and toners

are all filled up. This is really a marvelous invention

that have helped us so much in production!

Although we are still rely on image setter for high

fine dot reproduction, but 80-90%

of the jobs are done by the Laser Black Enhancer. We

all love it very much!

China / ShenZhen / The-Hon Cheng

GiFong corrugated plate process co.

We are based in Taiwan and start our plate making

business for corrugated board printing since 1999,

now we have 6 plants located in China. All of our

plants are using Laser Black Enhancer to make negative

film for our photopolymer plate making, we appreciate

to have this brand new invention to make film and

heard of that they have been granted inventions and

patents in 20 countries including USA, Germany, Japan…..etc.

We used to have a camera and darkroom in each plant

to make negative film for a long time, while Laser Black

system is only using a HP Laserjet printer, at the

beginning we all afraid of the opaque density will

be not good enough for the longest 7mm thick photopolymer

plate exposure, however, Laser Black Enhancer has a

Super Black Cartridge and proved the quality of 300%

black density increase immediately after drying, now

we have cleared more room for us by drawing away the

camera and film processor by tearing down the darkroom

completely.

We are using HP laserjet printer to print the image

on tracing paper / transparent film

and go through the Laser Black Enhancer to get the

high black density negative film to expose the photopolymer

plate directly, this save us much of time, labor,

cost and get very good efficiency, during this high

price competition to have more productivity and cost

saving are really very important for managements.

Only very few times for the gradation back ground

or the color separation jobs, we have to rely on an

image setter service center. Actually over 90% of

the films are made by Laser Black Enhancing System,

now we have 6 units of LB-A3 enhancers used in our

factories satisfactorily.

China / QunSan / John Chang

|

| P

R E S S R E L E A S E

- A brand new system for long-format film output - |

Laser Black Enhancer for black density enhancement, created

and developed by @Flexo group is now granted patents

in Germany, France, UK, Japan, Korea, Brasil, China,

HongKong, Taiwan and it is pending for other areas in

a total of 20 countries. The marketing of this brand

new product around the world has been proceeding by

attending the world class / national wide professional

printing exhibitions as EmbaxPrint (May 20 2003, Brno

/ Czech) and IGAS 2003 (Sept. 22, Tokyo / Japan) as

well as the INDOMAF (April 24 2003, Jarkata / Indonesia)

and Asia Print & Pack (June 6 2003, Bangkok / Thailand).

The product has been accepted and welcomed widely by

label, screen printers and package printing industries.

Just a laser print on a translucent paper or a trasparent

film, go through our Laser Black Enhancer, the print

can be 300-400% darkened in black density (over 3.5),

no matter it is a positive or negative. This is good

enough for any kind of plate exposure, do not have to

use image setter or photo-film from a reproduction camera

anymore. It is very simple and easy, everybody can do

it. Even a most opaque density needed, the longest exposure

time for a 7 mm thickness photopolymer plate can be

exposing directly for corrugated board printing.

A new long-format printer at the price as economic as

an A3 printer can print max.size of 33 x 90 cm is now

also available. The LB-3390 Laser printer offers true

multi-platform printing, with PostCript and PCL languages

built in, the printer can handle jobs from Macintosh,

Windows, UNIX and DOS platforms and it is ready to plug

into any network right out of a PC. All halftones can

be printed consistently regardless of line frequency

or resolution and features 35 PostCript fonts, 15 PCL

fonts up to 250 download fonts. The printer is designed

to last for well, over one-half million pages of output

combines speed, reliability and flexibility.

This long-format printer combines with Laser Black A3

Enhancer is already become a

new trend as an Economic Lager Format Film Output System.

In addition to its versatile, reliable and economical,

saving the invests of image setter, camera, film processor

and do not have to use photo-film any more as well as

no skillful people is needed, everybody can do it. Many

printers have seen the system as a new, low-cost and

convenient way as a Film Outputter.

Most important is that we use hi-tech chemical as our

Laser Black Enhancing Solution. This is a non-toxic,

environmental green and friendly product with a very

pleasant and fresh odor, after operation, you may just

wash your hands by only tap water. (031001)

|

| Not

only sell product we also sell legend |

Laser Black ENHANCER - A new solution for graphic images

The photographic film used for reproduction has been

existed for over 50 years, in the old days, if you want

to make a film for printing plate making, you have to

use only the traditional way by a reproduction camera,

a film processor or even a film copying machine. And

have to be done by a skillful technician, not only paying

much for the equipments but also time consumes. Nowadays,

the job can be done by a film outputing machine either,

however, the investment of it, is much more than the

above mentioned traditional machine.

With a Laser Black Enhancer, you can use the existing

PC (Windows or Mac) with a laser printer which you are

currently using, to make prints on a tracing paper or

transparent film first then go through our Laser Black

Enhancer, now you get a film ready for plate making.

Our system can make your B/W prints darkened with an

opaque density over 3.5 good for all kinds of plate

exposure (even a photopolymer plate in 7 mm thickness).

Everybody can do it, do not have to rely on a skilled

personel any longer, shorten the processing time as

well as no special trainning is needed.

Laser Black Enhaner is now available in A4 (250m/m

in width),A3 (360m/m), A1 (760m/m) and A0 (960m/m) with

no limitation in length as long as it is a print from

a B/W Laser Printer / Plotter. From now on you do not

need a film outputing machine or to buy a camera, a

copy machine even a film processor. You also do not

need to depend on anybody to make film for you, you

can make it easily by yourself, reducing your production

cost and the time wasteb.

Environmental green and friendly is now an important

and necessary issue, Laser Black? Enhancer is a non-toxic,

green chemical, after operation just clean your hands

with water, which is far, far ahead from polution contained

film developing chemicals and toxic solvents.

|

|

|

|